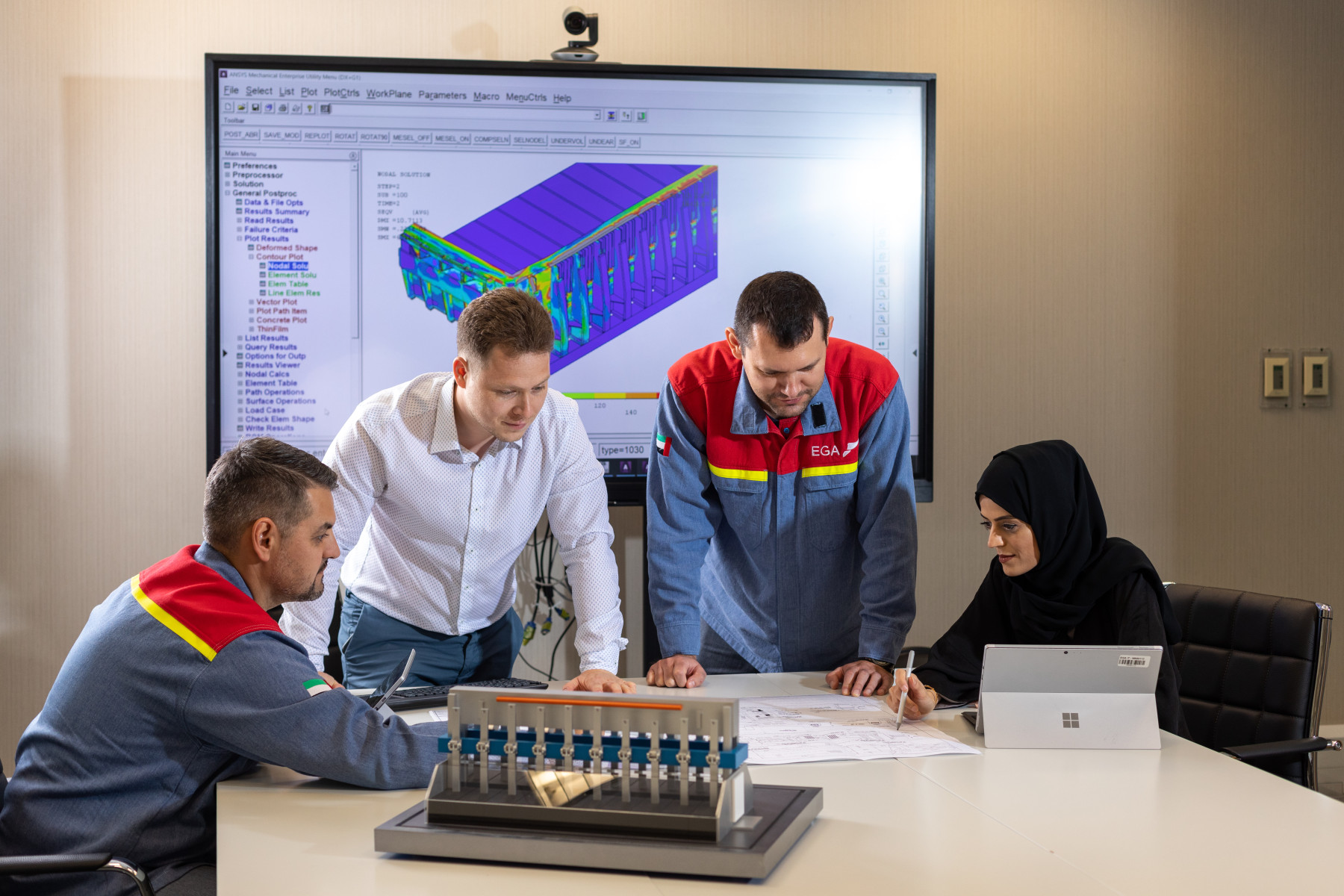

Emirates Global Aluminium (EGA) has announced the completion of the design phase of the company’s next generation smelting technology, EX.

It has been designed with two variants - one to maximise productivity and the other to further minimise greenhouse gas emissions.

Reduced electricity consumption, lower net carbon consumption, and reduced incidence of anode effects are expected to cut greenhouse gas emissions per tonne of aluminium produced by around 5% for the more productive variant and around 12% for the lower energy variant.

EGA is looking to build 10 pilot EX reduction cells at the company’s aluminium smelter in Al Taweelah to test and validate performance. The target is that EX is ready for full industrialisation by 2028.

According to EGA, the EX reduction cells are larger than its most recently industrialised technology DX+ Ultra, enabling higher amperage and improved current efficiency, increasing production capacity by up to 22 percent.

DX+ Ultra is already one of the most efficient smelting technologies in the global aluminium industry, said a top official.

"Technology development has been a foundation of our global competitiveness for decades. EX technology will enable the production of more aluminium with less energy and lower emissions, unlocking opportunities for EGA’s growth and helping us to meet the increasing global demand for the low carbon primary aluminium required to reach net zero by 2050," remarked its CEO Abdulnasser bin Kalban.

Innovations in the design of EX technology are expected to deliver enhanced pot performance with improvements to busbars, superstructure and potshells, leading to lower surrounding temperatures and better working environment, said Kalban.

The new technology was developed over 18 months by EGA’s Technology Development Design team. The pilot reduction cells are expected to be commissioned during the first quarter of 2025, he added.

-TradeArabia News Service