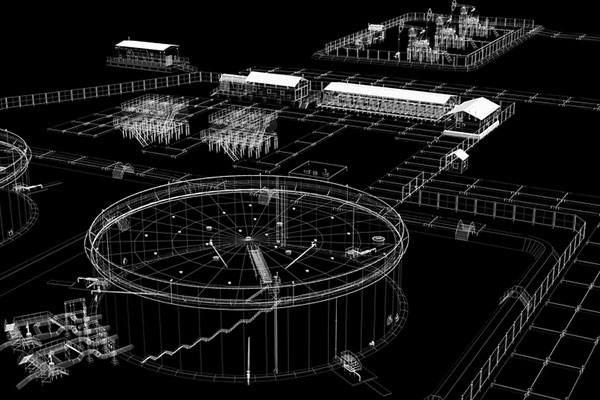

Creating a digital future for oil and gas

DUBAI, March 30, 2016

The oil and gas industry is facing a new productivity transformation, where digital technologies help companies discover new ways to drive increased efficiency, says a new report from global consulting services company Accenture.

The 2016 Accenture and Microsoft Upstream Oil and Gas Digital Trends Survey identifies the key trends driving digital investment in the oil and gas industry. Accenture’s Global Digital Energy senior manager, Brian Richards, explores how these trends can help oil and gas companies drive value in their businesses.

Accenture has created a framework to help clients think about how digital technologies will impact their business. It includes the augmentation and automation of both physical and mental processes.

Augmenting physical processes includes wearable computing, whereby workers in the field can see what someone sees, hear what someone hears, and help them with maintenance, training, safety and so on.

“If we take that to the next level, we’re looking at automating physical processes – things like drones and robotics, and using drones for flare stack inspections, pipeline surveillance, inspections at height and even post hurricane analysis,” said Richards.

“If we look at augmenting mental or cognitive processes, this includes analytics or the internet of things, and how companies can use data to make better decisions with the data they have.

“In the fourth quadrant we have the automation of mental processes, and that’s where we’re removing the worker altogether and we’re using things like cognitive computing and machine learning to make decisions with the data we have, which in many cases is beyond human ability.

“Taken together these four quadrants paint a picture of how oil and gas companies can use digital technology to drive increased efficiency in the oilfield,” he explained.

Wearables

Augmentation technologies such as wearable computing present new and exciting ways for workers to help them make faster, better decisions. While technologies such as head mounted displays and smart watches are improving safety and contributing to process efficiencies, there are a number of challenges that must be overcome for oil and gas companies to realise their true value.

Wearable computing comes in many different forms – head mounted devices, smart watches, smart clothing. The way companies are using this really falls into a few different form factors.

“The first is what we call “over-the-shoulder-coaching”. This is when a worker in a remote location can see what you see, hear what you hear, and help you with maintenance, training, safety issues and so forth,” said Richards.

And that really changes how workers need to be deployed, and helps workers make better decisions, faster.

The second opportunity is around heads-up displays, where a worker can have real-time process information and location information put into their field of vision so they can follow a process or procedure as they’re actually doing the work.

The third opportunity is full-augmented reality: the ability to look at a piece of equipment, a dial or gauge, and overlay real-time information to make better decisions.

Taken together this journey will change how field work is done, and represents the next evolution of mobility.

There are certainly challenges. For example intrinsic safety. Most devices on the market today are not intrinsically safe. Battery life is another concern–most devices only last a few hours right now. Another concern is around user comfort.

What are some of the things people can take action on today? The first is to reimagine your processes as if you had this capability, and really look at the role of mobility to augment your workforce, to take you from productive to hyper productive.

Drones

Drone technology is already improving safety in the oil and gas industry by removing the need for workers to operate in high-risk environments. Pipeline surveillance, post-hurricane analysis and flare stack inspections are just some of the ways drones are safely capturing new sources of data. But with legal challenges mounting, how can the industry effectively maximize the potential of this technology?

The second quadrant is about automating physical processes –using technology to remove a worker from the field. One example of this would be drones.

The oil and gas industry has been a leader in robotics for some time.

Drones represent the next frontier. By using drones there are many different opportunities to drive greater productivity.

One example is flare stack inspections. Right now workers need to build scaffolding around flare stacks to do inspections, and the flare stacks need to be shut down.

With drones we can use specialized cameras to fly around flare stacks and capture new sources of information without putting the worker in danger. Another example is pipeline surveillance, where we can fly over pipeline right-of-ways and look for leaks, right of way intrusions and other issues.

The third opportunity is post hurricane analysis for offshore platforms. We can fly a drone offshore to see if platforms are ready for operations after hurricanes.

There are even innovative opportunities for drones such as flying in remote locations and capturing data from remote locations and bringing that back for analysis.

There are many opportunities for drones, but there are also many challenges. One is around legal. It requires many permits and processes to legally fly drones in different countries, and each country has its own legal framework. Working through that and moving beyond an ad-hoc manner creates a significant challenge.

And that really creates an opportunity for how companies can take drones to the next level. Which is to run drones more as a service, create the ability to capture all this data, store it in a standard format for different drone operators, and allow people across the company access to that data for analysis and interpretation.

Analytics

Data analytics provide a systematic way to make sense of the large volumes of data being collected across the entire oil and gas value chain. This can help predict when a machine will fail, or ensure that resources are in place where needed. Extracting business insights however takes the right digital platform and the right talent.

The third quadrant is all about how we can augment mental processes.

Every day oil and gas companies make thousands of decisions for better or worse, based on little more than gut feeling and experience. Data analytics really present an opportunity to move beyond that.

Oil and gas companies have been looking at and implementing data and analytics for a long time. But a lot of the time we stop short at business intelligence and reporting. If we take it further with technology like big data or cloud computing there’s a lot more opportunity.

For example production optimization: taking data from artificial lift systems, from the reservoir and elsewhere to make better production decisions. Another example is predictive maintenance: taking data from machines and looking for not just is it going to fail, but when and how.

“Another example is supply chain – we can take the data from trucks and other equipment and logistics and say whether something is where it should be, when it should be,” said Richards.

To enable those type of user cases you need the right data platform and the right talent. In many cases companies have neither. So for the right data platform there are two ways to look at it –one is internally, building from scratch, the other is externally –buying it as a service from an external provider or vendor.

For talent, companies are looking outside the industry to bring in data scientists, quantitative folks, mathematicians to be able to help solve some of these challenges and teach them the industry to drive these analytic solutions.

Cognitive computing

Cognitive systems and machine learning allow decisions to be made automatically, with the help of complex algorithms that can interpret large volumes of data. While this can optimize production and increase safety, are oil and gas companies ready to turn over decisions to a machine?

The fourth quadrant is all about automating mental processes and decisions. In many ways this is the hardest area for companies to master, as the technology is so new. What we’re talking about here is taking the data from the field, pipelines, plant and elsewhere and using machine algorithms, cognitive computing, machine learning to make decisions automatically, the report said.

“We’ve already seen how this can transform other industries, for example on Wall Street: an activity which used to be highly manual and human intensive like trading is now primarily bots and computer algorithms trading with other bots and computer algorithms,” said Richards.

“So in the oil and gas industry when we think about the amount of data coming from these different systems, it’s only natural for us to apply cognitive systems and machine learning to automatically make decision in the best interest of the company.”

Optimize production, increase safety, increase logistics and transportation efficiency.

There are many different challenges. Probably the biggest challenge is the technical limitation that exists today. In companies not being comfortable turning over processes and decisions to a machine.

“The way you should get started is to look at low risk areas where you can try the technology and learn,” said Richards.

“For example helpdesk, where you’re combining many different documents from diff systems and providing that info back to a worker.

“Once you’re comfortable with the technology you can move into front office applications such as production optimization or artificial lift optimization which is really core to your business,” he concluded. – TradeArabia News Service