The Centum VP

Yokogawa to release Centum VP R6.10

TOKYO, November 22, 2022

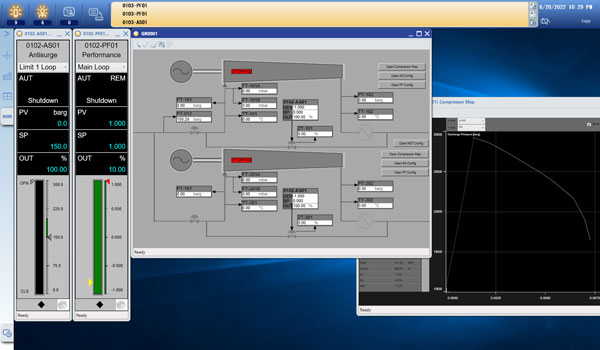

Yokogawa will soon release Centum VP R6.10, a new version of the firm’s integrated production control system that enables the steam turbine control for compressor drive and the integrated control of multiple compressor trains.

With this release, new functionality is enabled for the CCC Inside for Yokogawa Centum VP solution that was jointly developed by Compressor Controls LLC (CCC) and Yokogawa. In addition to allowing process control and turbomachinery control to be carried out on the same Centum VP system, the scope of control that can be performed with a single system has been extended, allowing the streamlining not only of operations, but also of engineering, procurement and maintenance.

Development background

Conventionally, different systems have been used to control processes and the large number of turbomachines found in plants, meaning users had to manage and operate multiple systems.

To address this issue, Yokogawa worked with CCC to develop CCC Inside for Yokogawa Centum VP. Released in November 2021, this solution enables Centum VP to control both processes and turbomachinery.

For the many different steam turbines and compressor trains that are found in plants, customers want to be able to expand the scope of control and streamline operations, engineering, and maintenance by using a single production control system.

To enable the steam turbine control for compressor drive and integrated control of compressor trains and expand the scope of control with CCC Inside for Yokogawa Centum VP, Yokogawa has developed this latest release of the Centum VP system.

Main Features

*Expanded scope of control with support for steam turbine control for compressor drive

With this release, it is now possible for CCC control algorithms running on Centum VP to control steam turbines for compressor drive. This allows whole compressor system which contains steam turbine control to be monitored and controlled from the same human-machine interface (HMI) used for conventional process control. The ability to use the same hardware to perform these functions simplifies engineering, procurement, and maintenance, reduces the need for spare parts, lowers maintenance costs, and helps to reduce the workload for maintenance planning and implementation.

*Optimisation through the integrated control of multiple compressor trains

Yokogawa has enabled the control of multiple compressor trains, of which many can be found in customers’ plants, by working with CCC to develop a function block for the integrated control of multiple compressor trains, and has realised overall optimised control through the distribution of the compressor load.-- TradeArabia News Service